|

Washin System Solution Sdn Bhd is a local company founded in 2018. With offices in Klang Valley, we are strategically located to support our customer sites anywhere in Malaysia.

We are a driving force for Process Improvements through automation and industrial information systems, delivering step improvements in reliability, cost reduction, energy efficiency, productivity, yield and unmanned operation. Our core beliefs include: Meeting and exceeding our customer’s expectations, being flexible and easy to work with, delivering real benefits and providing responsive local support for all types of automation and industrial SCADA /IT in Malaysia. We are more than just an automation system integrator and focus to understand our customer’s plants and processes and ascertain performance and potentials. We offer Control, Automation, Industrial Plant Information and Electrical Engineering solutions, services and systems integration. Our team are experienced in PLC, SCADA, Failsafe and Fault-tolerant PLC, Safety Systems, Industrial Data Processing, Traceability, Communications, Medium and Low Voltage, Distribution Board, Waste Water and general industrial utilities. Our key markets are for robust applications requiring innovation, very high reliability, long life and special know-how involving critical utilities with zero interruption tolerance. Success is to be ahead in delivery of cost benefit and advantage to our customers through smart, solid, winning solutions that withstand the test of time and optimize balance between technology and practical real-world operability. Our people are focused to constantly grow their capability and know-how in the technology and application fields in which we operate. |

Our Core Business Include as below:

Plant Automation and Management Systems

Washin System Solution Sdn Bhd solutions and services cover plant automation model that defines interfaces between enterprise and manufacturing control systems.

|

Manufacturing Operations Management

|

Design and supply of systems for MES, Traceability management, downtime and scheduling, track and trace, quality control.

|

|

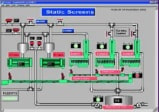

Supervisory Control

|

Design, supply and configuration of SCADA, Batch Control, DCS and Communications

|

|

Plant Control

|

Design, supply and configuration of PLCs and DCSs.

Specification and Configuration of Main Control's Instruments etc. |

|

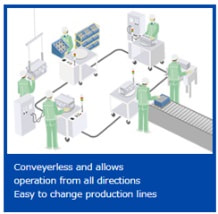

AGV

|

Automated Guide Vehicles

|

|

Picking System

|

Pokayoke & Andon Picking System

|

SCADA/PLC

|

Washin System Solution Sdn Bhd supply turnkey PLC/SCADA automation solutions as well as upgrades and extensions and support for existing and legacy systems.

Projects have utilized PLC and DCS from major manufacturers including Allen Bradley, Mitsubishi, Schneider Electric and Siemens. SCADA Projects have been completed on Wonderware System Platform, Wonderware InTouch, Cimplicity, Citect and WinCC. We specialize in high availability, fault tolerant and Safety PLC solutions. Many of our projects involve zero-interruption tolerance applications where structured software design is essential to achieve the required level of reliability. High availability hardware platforms including redundant CPU and I/O hardware and hot-swap modules have been employed. |

Services

- User Requirements and Systems Architecture Definition

- Detailed Control Functional Requirements

- Turnkey System Integration Services

- Installation Supervision & Commissioning

- System Support

MES

Manufacturing Execution Systems (MES) enable customers to better control batch manufacturing activities. Our MES solutions are tailored to customer process requirements and typically include manufacturing instructions, recipe management, recipe download to batch automation and up to fully automated batch manufacturing

It provides robust procedure control minimizing holdup’s and facilitating controlled intervention. Solutions are tailored to the customer’s process and business needs, and can range from replicating existing paper based recipe manufacturing to replacing prompted instructions with full recipe controlled batch automation in part or fully.

While our solution utilizes out-of-the-box functionality from companies such as Wonderware, Citect or Cimplicity, our strengths lie in tailoring solutions to meet customer’s business needs, integrating with plant automation and accommodating legacy systems

Manufacturing Execution Systems (MES) enable customers to better control batch manufacturing activities. Our MES solutions are tailored to customer process requirements and typically include manufacturing instructions, recipe management, recipe download to batch automation and up to fully automated batch manufacturing

It provides robust procedure control minimizing holdup’s and facilitating controlled intervention. Solutions are tailored to the customer’s process and business needs, and can range from replicating existing paper based recipe manufacturing to replacing prompted instructions with full recipe controlled batch automation in part or fully.

While our solution utilizes out-of-the-box functionality from companies such as Wonderware, Citect or Cimplicity, our strengths lie in tailoring solutions to meet customer’s business needs, integrating with plant automation and accommodating legacy systems

|

AGV systems

AGV offers state-of-the-art Automated Guided Vehicle traffic control solutions for applications ranging from single vehicle to complex integrated multi-AGV systems. A variety of systems are available for different requirements and applications. The main features of the full-scale AGV systems are: · Windows/PC based client/server technology · Continuous narrow band or WLAN communication to AGV’s · AGV Traffic management- collision avoidance & route optimization · AGV Transport order management · User-friendly graphical interface · Interfaces to other computer systems and I/O · Easy configuration, expansion, and modification of the AGV routing · Extensive Event Logging and Diagnostics |

|

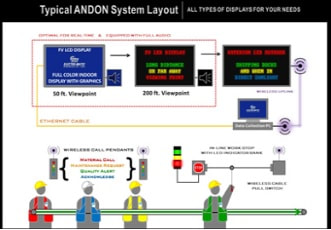

Picking Solution & Andon System

Our Projection Picking System (PPS) applies image processing technology that is flexible enough to accommodate various shapes of rack and shelf configurations. In addition, the built-in error-proofing features can facilitate picking operation in logistics centers and on plant assembly lines. It can also be installed in places where you cannot mount light modules. |

|

Andon System

An Andon is a visual and audible response notification tool, which is comprised of various combinations of lights and sounds. When production personnel have any issue on the floor, they simply turn on the Andon to signal for help. Once the system is turned on, the lights and sounds alert the support personnel who can quickly address the problem. An Andon promotes visual factory and serves two goals. First, it enables the production personnel to remain at their workstation when they have an issue. Second, it reduces response time and more efficiently gets the support personnel to the line where they are needed to get the line back up and running. · Configurable using numeric, alphanumeric marquees and light block · Incandescent or LED lighting in three colors (red / green / amber) · Inputs include PLC's / Discreet / RS232 / RS485 / Ethernet 10 Base T / DeviceNet / CC-Link / CC-Link IE · Horn / Music Outputs |

Support Team

System Support

Washin System Solution Sdn Bhd provide scheduled and unscheduled site maintenance and 24/7/365 systems support. Support packages are tailored to suit each individual customer needs and minimum response times are guaranteed.

Scheduled System Review & Maintenance Report

It is important that our engineers maintain familiarity with normal plant system operations to enable our engineers to adequately support the system when the need arises. This is achieved through scheduled site visits and reporting.

The work schedule typically includes:

Perform the tasks outlined in the maintenance report document

System Support

Washin System Solution Sdn Bhd provide scheduled and unscheduled site maintenance and 24/7/365 systems support. Support packages are tailored to suit each individual customer needs and minimum response times are guaranteed.

Scheduled System Review & Maintenance Report

It is important that our engineers maintain familiarity with normal plant system operations to enable our engineers to adequately support the system when the need arises. This is achieved through scheduled site visits and reporting.

The work schedule typically includes:

Perform the tasks outlined in the maintenance report document

- Complete minor system improvements if required

- Troubleshoot ongoing investigations / snag lists e.g. checking records for items “ongoing”

- Tuning of the system where relevant

- Check the main system/server resources

- Install routine product updates and patches as they issue

- Complete a summary report giving the status of the system

Culture

On-going Learning

On-going Creating

On-going Developing

Motto

Innovations towards Smart Factory Automation

Vision

To be Malaysia Leader in Smart Factory Automation Engineering Team

On-going Learning

On-going Creating

On-going Developing

Motto

Innovations towards Smart Factory Automation

Vision

To be Malaysia Leader in Smart Factory Automation Engineering Team